Common Food Truck Build Mistakes (And How to Avoid Them)

- David Silverberg

- Dec 26, 2025

- 3 min read

Building a food truck is one of the most expensive and irreversible steps in starting a mobile food business. Unfortunately, many first-time operators discover—too late—that small oversights during the build phase can lead to failed inspections, costly rebuilds, downtime, or complete shutdowns.

This guide breaks down the most common food truck build mistakes and explains exactly how to avoid them—before they cost you tens of thousands of dollars.

Mistake #1: Buying a Truck Before Understanding Local Codes

One of the most common—and most expensive—mistakes.

Health, fire, and building codes vary by city and state. A truck that passed inspection in one jurisdiction may be illegal in another.

Common consequences:

Failed health department inspections

Forced rebuilds

Denied operating permits

How to avoid it:

Review local health and fire codes before buying or building

Confirm hood, plumbing, electrical, and propane requirements in writing

Work with builders familiar with your jurisdiction

Mistake #2: Ignoring Payload & Weight Calculations

This mistake alone can render a truck completely unusable.

Many trucks exceed their Gross Vehicle Weight Rating (GVWR) once equipment, water tanks, propane, and staff are added.

Common consequences:

Unsafe driving conditions

Failed DOT inspections

Voided insurance

Premature mechanical failure

How to avoid it:

Perform full payload calculations before the build

Account for water (8.34 lbs per gallon), equipment, and inventory

Choose the correct chassis—not just the cheapest one

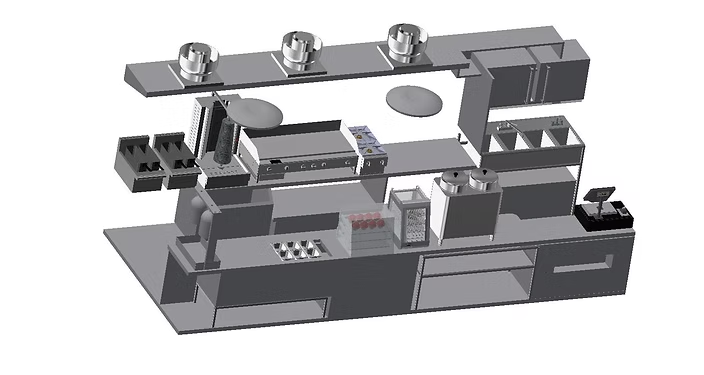

Mistake #3: Poor Kitchen Layout & Workflow Design

A kitchen that looks good on paper can be inefficient—or dangerous—in practice.

Common consequences:

Bottlenecks during service

Increased staff fatigue

Higher injury risk

Slower ticket times

How to avoid it:

Design layout based on menu flow, not aesthetics

Separate hot, cold, prep, and service zones

Leave adequate aisle clearance for safety and code compliance

Mistake #4: Undersized Electrical Systems

Modern food trucks rely heavily on electricity—yet many builds underestimate power needs.

Common consequences:

Tripped breakers

Equipment failures

Generator overload

Fire inspection failures

How to avoid it:

Calculate electrical load for all equipment

Plan for peak simultaneous usage

Install commercial-grade wiring, panels, and shore power

Mistake #5: Cutting Corners on Ventilation & Fire Suppression

Ventilation is not optional—and mistakes here are rarely fixable cheaply.

Common consequences:

Fire department rejection

Insurance denial

Excessive heat and smoke

How to avoid it:

Install a properly sized Type I hood when required

Use certified fire suppression systems

Ensure professional installation and documentation

Mistake #6: Improper Plumbing & Water Tank Sizing

Water systems are one of the most heavily regulated parts of a food truck.

Common consequences:

Failed health inspections

Inability to operate legally

Forced tank replacement

How to avoid it:

Meet or exceed minimum tank ratios (fresh, grey, waste)

Install accessible cleanouts and backflow prevention

Use NSF-approved materials

Mistake #7: Using the Wrong Materials

Not all materials are acceptable in a commercial food environment.

Common consequences:

Failed inspections

Accelerated wear and corrosion

Difficult cleaning and sanitation issues

How to avoid it:

Use commercial-grade stainless steel

Avoid decorative or residential materials

Choose slip-resistant, sealed flooring

Mistake #8: Skipping Documentation & As-Built Records

Many owners don’t realize documentation is required—until inspectors ask for it.

Common consequences:

Inspection delays

Permit denial

Difficulty making future modifications

How to avoid it:

Keep schematics for electrical, plumbing, and propane systems

Retain equipment spec sheets

Document weight and load calculations

Mistake #9: Choosing the Wrong Builder

Not all builders understand food truck regulations—or build quality.

Common consequences:

Poor workmanship

Missed deadlines

Non-compliant builds

Costly legal disputes

How to avoid it:

Verify past builds and references

Demand written specifications and timelines

Avoid builders who guarantee “approval anywhere”

Mistake #10: Not Budgeting for Revisions & Delays

Even the best builds encounter issues.

Common consequences:

Cash flow problems

Delayed launch

Compromised quality

How to avoid it:

Budget a 10–15% contingency

Build extra time into your launch schedule

Plan for inspection revisions

Final Thoughts

Most food truck failures don’t start on the street—they start during the build.

Avoiding these common mistakes can mean the difference between a truck that passes inspection smoothly and one that becomes an expensive liability.

The smartest operators invest in planning, compliance, and professional guidance before committing to a build.

Want to Avoid Costly Food Truck Build Mistakes?

Before you buy a truck or sign a build contract, get clarity.

👉 Free Food Truck Build Review

In a one-on-one consultation, we’ll:

Review your concept and menu

Identify compliance and weight risks

Flag build decisions that commonly fail inspections

Help you avoid expensive redesigns

A short review upfront can save you $20,000+ in rebuild costs.

👉 Schedule your free consultation today

Comments