Food Truck Layout and Design: The Difference Between a Struggling Truck and a Profitable One

- David Silverberg

- Dec 27, 2025

- 4 min read

Every food truck starts with a vision—but not every food truck succeeds.

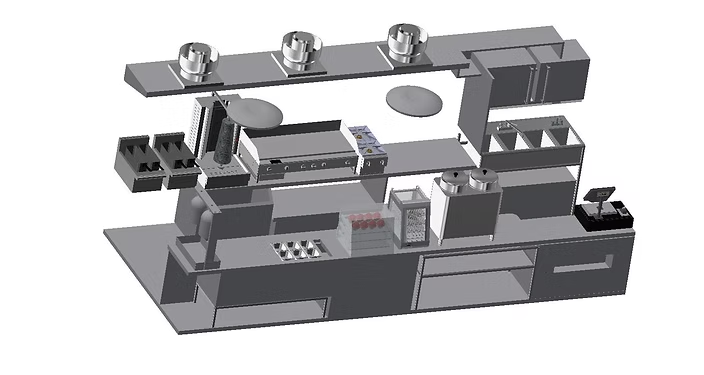

More often, success comes down to layout and design. A poorly designed food truck slows service, frustrates staff, fails inspections, and quietly drains profits every single day. A properly designed truck, on the other hand, works like a well-oiled machine—faster, safer, compliant, and built to scale.

Food truck layout is not about squeezing equipment into a box. It’s about engineering a mobile kitchen that works for you, not against you.

Why Food Truck Layout Is Where Most Operators Lose Money

Many first-time food truck owners make the same costly mistake: they buy or build a truck before fully planning the layout. Equipment gets placed where it fits—not where it should be. Utilities are added as an afterthought. Workflow is ignored.

The result?

Long ticket times during peak service

Staff bumping into each other

Failed health or fire inspections

Overloaded vehicles and mechanical issues

Expensive rebuilds after the truck is already on the road

A food truck is too small—and too expensive—to fix mistakes later. Layout decisions made upfront determine whether your truck makes money or bleeds it.

Your Menu Should Drive the Design—Not the Other Way Around

One of the biggest red flags we see is a truck designed before the menu is finalized. This almost always leads to compromises that hurt operations.

A profitable layout begins with clear answers to critical questions:

What exactly are you serving?

How many items are cooked, reheated, or assembled?

How many staff will work during peak hours?

How fast do orders need to go out?

A burger truck, taco truck, pizza truck, or dessert truck all require completely different layouts. When the menu drives the design, every piece of equipment earns its place—and every inch of space generates value.

Workflow Is the Engine of Your Operation

In a food truck, every step matters. Poor workflow doesn’t just slow you down—it costs you sales.

A professionally designed layout creates a smooth, logical flow:

Storage

Prep

Cooking

Service

Cleaning

When workflow is optimized:

Orders move faster

Staff work efficiently under pressure

Mistakes decrease

Lines move quicker

Revenue increases

When workflow is ignored, even great food can’t save a chaotic operation.

Equipment Placement: Where Experience Pays for Itself

Improper equipment placement is one of the most expensive mistakes in food truck builds.

Health departments and fire marshals require strict clearances, ventilation coverage, and access to shutoffs. If equipment is placed incorrectly:

Inspections fail

Openings are delayed

Equipment must be relocated

Thousands of dollars are wasted

A professional layout accounts for code compliance, safety, and efficiency at the same time—so your truck passes inspection the first time and opens on schedule.

Weight Distribution: The Silent Truck Killer

This is one issue that sinks more food trucks than owners realize.

Every truck has a maximum payload capacity. When layout and equipment weights aren’t calculated properly, trucks become overloaded—sometimes dangerously so.

Consequences include:

Suspension and brake failures

Unsafe handling on the road

Voided warranties

Failed inspections

Trucks that are legally unusable

Smart layout design includes precise weight calculations and balanced placement of heavy components like water tanks, generators, and cooking equipment. Ignore this step, and your truck may never perform as intended.

Utilities Done Right = Reliable Daily Operations

Your truck’s water, electrical, and gas systems are not the place for guesswork.

Poor utility planning leads to:

Insufficient power during service

Running out of water mid-shift

Overloaded generators

Fire code violations

A properly designed layout integrates utilities seamlessly:

Correctly sized water and grey tanks

Electrical systems matched to actual load

Battery or generator and shore power compatibility

Safe, accessible propane systems

When utilities are designed correctly, your truck runs smoothly day after day—without surprises.

Ventilation: Protect Your Staff, Equipment, and Investment

Heat, smoke, and grease build up fast inside a food truck. Inadequate ventilation creates miserable working conditions and shortens the life of your equipment.

A professional ventilation design:

Matches hood capacity to cooking output

Maintains safe temperatures

Reduces maintenance costs

Meets fire code requirements

Better ventilation isn’t a luxury—it’s essential for productivity and compliance.

Storage: The Hidden Profit Multiplier

Storage is often underestimated, yet it directly affects how much money you can make in a day.

Insufficient storage means:

More trips to commissaries

Smaller menus

Slower service

Higher labor costs

A smart layout maximizes storage without sacrificing workflow—allowing longer service windows, higher volume, and more flexibility.

Designed for Growth, Not Just Opening Day

Many trucks are built to “just get open.” The best trucks are built to grow.

A future-ready layout allows for:

Menu expansion

Equipment upgrades

Higher service volume

Catering and special events

Planning ahead costs far less than rebuilding later.

The Bottom Line: Layout Is Not an Expense—It’s Insurance

Your food truck layout determines:

How fast you serve

How much you sell

How easily you pass inspections

How long your truck lasts

How stressful your daily operation becomes

Cutting corners on design almost always leads to higher costs down the road. Investing in a professionally planned layout protects your budget, your timeline, and your business.

A food truck should work as hard as you do.

Comments